What’s the Fashion Industry got to do with 3D Printing?

Fashion is one of the most dynamic industries in the world. In this fourth industrial revolution, the fashion industry too has embraced change, leveraging new technologies to spur innovation. Designers are adopting the use of 3D printers to manufacture both accessories and garments.

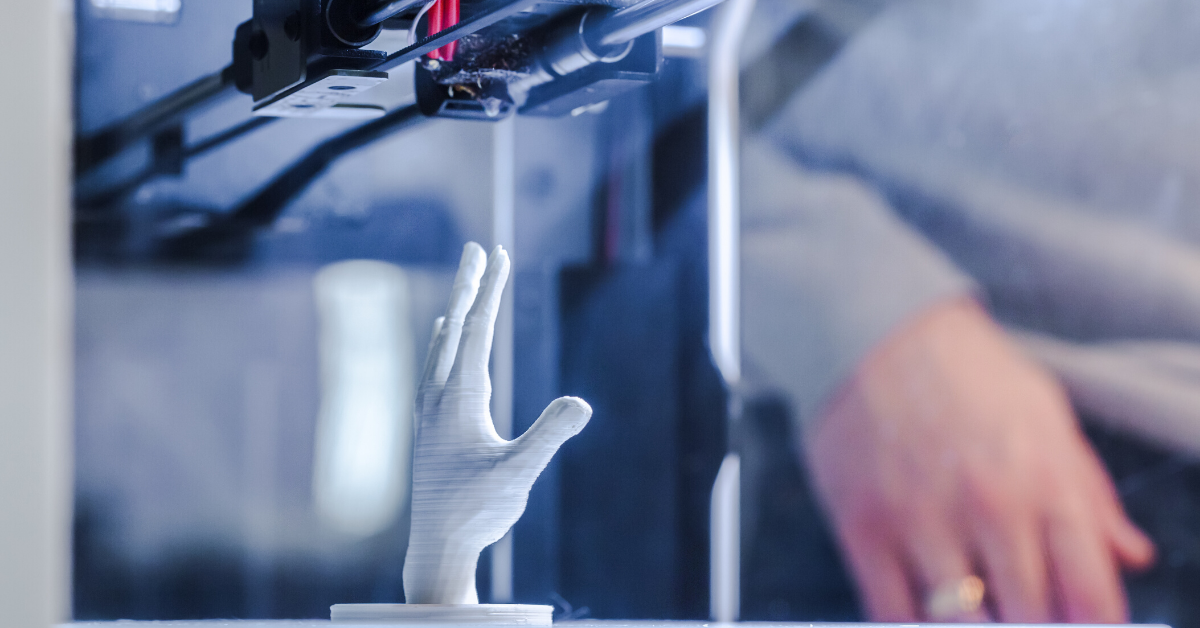

Professionally known as additive manufacturing, 3D printing is a process that allows an individual or company to “print” any design in a three-dimensional form. The range of applications is endless – toys, robots, instruments, tools, mechanical parts, and, yes, fashion.

The bright side

For technology and engineering students who are interested in learning 3D printing techniques, there is no better time. Developing a specialization in the required applications, processes and tools is the key to creating value for businesses. Our learning pathway on 3D printing can help you gain relevant expertise.

Fashion designers, on the other hand, have to summon creativity while implementing 3D printing in their trade, as this technology has only recently gained momentum.

Flexibility issues with 3D printing

The process of 3D printing has posed a certain challenge to clothing designers since their creations need to be soft, flexible, and easy to put on. 3D printing machines, however, operate optimally with stiffer materials as inputs. Accessories designers have historically been able to print items that are naturally stiff, such as shoes and jewelry. Adapting 3D printers for wider application in an industry that requires creating flexible products demands improvisation.

Forward-looking designers remain on the lookout for materials that are both flexible and mechanically viable. Designer Mingjing Lin, for example, wanted more fluidity and dynamism in the clothes she created, so she 3D-printed textiles by combining thermoplastic polyurethane with traditionally pleated fabrics.

In 2016, Israeli designer Danit Peleg created a dress using a flesh-colored filament called FilaFlex, which is flexible enough for any movement yet durable enough to withstand the manufacturing process. Her ingenuity allowed to produce a dress that would allow for exacting dance movements.

Innovation leads to options

ln using 3D printing, designers are free to create intricate patterns and structures that are both aesthetically pleasing and functional.

Take for instance, the 2019 Academy Award winning 3D-printed headpiece used in the movie Black Panther. Designed by American costume designer Ruth E. Carter, in collaboration with Los Angeles-based Austrian architect Julia Körner, the creation was worn by Angela Bassett, who starred as Queen Ramonda. Another renowned American fashion designer, Zac Posen, created a dress constructed from 3D-printed petals; British model Jourdan Dunn wore it to the 2019 Met Gala in New York.

Garments made using 3D printers use mesh systems to overcome rigidity constraints. And, since a garment can be printed in parts and then pieced together, designers can include complicated patterns in individual segments. These segments can then be layered and assembled to create something extraordinary. This process, though it may seem long, is a more defined approach than the traditional manufacturing flow.

3D printing enables customization

Another advantage of 3D printing is the ability to customize pieces by accounting for different body shapes and sizes. This type of breakthrough has allowed for mass customization at affordable prices. Aside from mechanics, 3D printing also provides creative benefits to designers, allowing them to realize innovative projects that may not have been possible earlier.

The fashion industry is fast approaching a time when additive manufacturing might trump traditional manufacturing methods. The advances that the industry is seeing are taking place at a breakneck pace, thus creating a talent shortfall of qualified designers.

Therefore, budding fashion designers should prioritize building skills related to 3D printing and understand how the technology can benefit their work. In the years to come, 3D printers will become more cost effective and people will begin producing goods right from home. Get ahead of the curve and embrace a whole new avenue for creative output!